1. Material permeability

Any material has certain permeability and the only difference is that some material has high permeability while others have low. With low Permeability, polymer can be used to prevent the permeating of oxygen and vapor from the air, which maintains the special gas composition in the package and improves the guarantee period obviously.

Concern for package made of polymer or its relating material is permeability of common gases such as: oxygen, carbon dioxide, nitrogen and water vapor permeability, which could be represented by two indexes: permeability and permeation mass. The former is characteristic of material and it would not vary with material thickness and area change. While the latter is property of finished products and it changes with material thickness and structure transformation.

2. Gas permeability coefficient and permeation massGas permeability is usually assessed in terms of gas permeability (gas permeability coefficient) and permeation mass. Inorganic gas permeability is determined by solubility (S) and diffusion coefficient (D). Therefore, gas permeability coefficient, permeation mass, solubility and diffusion coefficient should be assessed comprehensively.

Permeability coefficient (P) refers to the amount of gas, by volume, which penetrates unit thickness and area of specimen per unit time, under constant temperature and unit pressure difference when permeation is stable, expressed in cm3·cm/cm2·s·Pa. While permeation mass (Q) refers to the gas volume which permeates through unit area of specimen per unit time, under constant temperature and unit pressure difference when the permeation is stable. Its unit is cm3/m2·d·Pa. They satisfy the following formulas:

d: material thickness

Units must be unified before calculation. For instance, the unit of permeability coefficient is cm3·cm/cm2·s·Pa and gas permeation mass cm3/m2·d·Pa. Testing time difference between the two units is 86400 times and area difference is 10000 times. Coefficient 1.1574×10-9 is provided for the unifying of units by GB 1038.

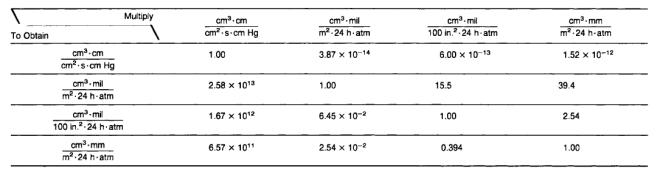

At present, definition of gas permeability index is in chaos. For instance, Gas Transmission Rate (GTR) in ISO standard (ISO 2556,ISO 15105-1)refers to gas volume which permeates through unit area of specimen per unit time, under constant temperature and pressure difference when permeation is stable (the same with GB 1038 standard). Its unit is cm3/m2·d·atm. While in ASTM D1434 standard, GTR refers to amount of gas, by volume that penetrates unit area of specimen per unit time in testing condition, expressed in ml(STP)/m2·d. Suggestion is that users should firstly ascertain data unit and then converse all comparing data to the same index before comparing. ASTM D1434 standard lists some unit conversion tables, of which is table 1, used for conversion between gas permeability units.

Table 1 unit conversion table of common gas permeability

Material water vapor permeability is assessed in terms of water vapor permeability (water vapor permeability coefficient) and transmission rate. However, the mostly used is water vapor transmission.

Water vapor permeability coefficient (PV) refers to water vapor volume that permeates through unit thickness and area of specimen per unit time, under specified temperature, relative humidity and unit vapor pressure difference, expressed in g·cm/cm2·s·Pa. Water vapor transmission (WVTR in ISO 2528, ASTM F1249) refers to amount of water vapor, by volume that penetrates one square meter and specified thickness of specimen within 24 hours, under specified temperature and relative humidity and water vapor pressure difference. The unit is g/m2·24. They satisfy the following formulas:

d: thickness of specimen

△p: water vapor pressure difference between two sides of specimen.

There is no mention of Water Vapor Permeance (P) in GB 1037 standard. But it is described in ASTM standard as follows: water vapor permeance that permeates through unit area of specimen pre unit time, under specified temperature, humidity and water vapor pressure difference between two sides of specimen. The unit is g/m2·s·Pa.

△p: water vapor pressure difference between two sides of the specimen

d: thickness material

Definitions of water vapor permeability indexes are very clear. They can be conversed according to table 2 (from ASTM E96).

Table 2. Unit conversion table of water vapor permeability

Note: pressure conversion between mmHg and Pa is at 0°C.

4. Notes

Firstly, testing condition including environment temperature and humidity should be considered in testing data comparison. Permeability indexes comparison should be under the same testing condition. Otherwise, simple data comparison is meaningless.

Secondly, material permeability testing (including gas and water vapor permeability testing) is not significant for all materials. It has practical significance in testing uniform and monolayer material. However, for multiplayer and composite material or finished product package film, permeance is vital while permeability testing is meaningless. In order to guarantee the accuracy, permeability testing of uniform and single layer material should be performed with more than one specimen.